Single-Use Mixers

for Biopharma & High Purity Processes

White Mountain Process offers disposable and single-use mixing, shaking, and blending technology for biopharma and high purity manufacturers. We cater to OEMs who are integrating mixers into their own single use process systems, and to end users who want customized single-use mixing designed to their specifications and requirements. Our offerings include:

- Mixer and agitator drives with various output speeds and motor configurations

- Variety of “wetted” materials available

- Including 316Lss, USP VI PE/PP/PVDF, Hast C, Titanium, and other exotic materials

- Variety of mixer connections for open containers and closed/sealed bags

- Custom designs for any single use mixing application

- Lab mixing to pilot scale blending to full scale agitation

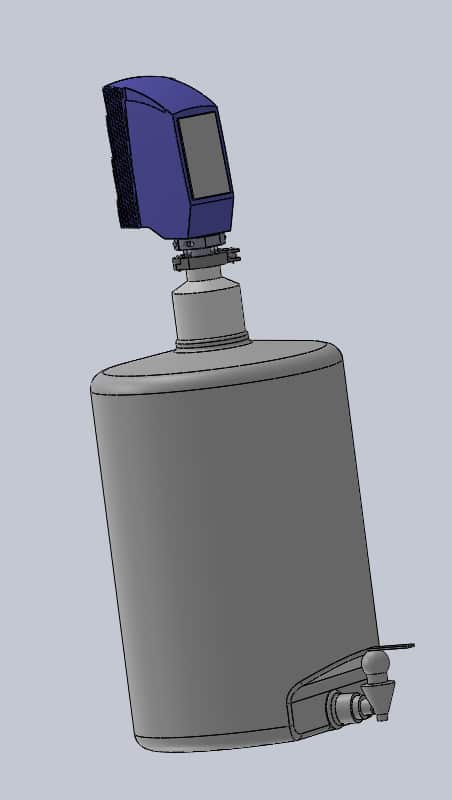

CLICK HERE for Sealed Carboy Mixer System Drawing

Single-Use Mixer Features

For disposable mixing with aseptic sealed disposable mixer & container

- Single use top entry mixer drive blending system

- Sealed sterile containers

- Disposable mixer and container setup

- Gamma radiated / sterilized mixing bags

- Full cert package

- Bottom entry mixing systems with NO moving parts (zero shedding, no particulate generation, eliminate CIP/SIP, no cross contamination between batches – White Mountain Process loves single use mixing)

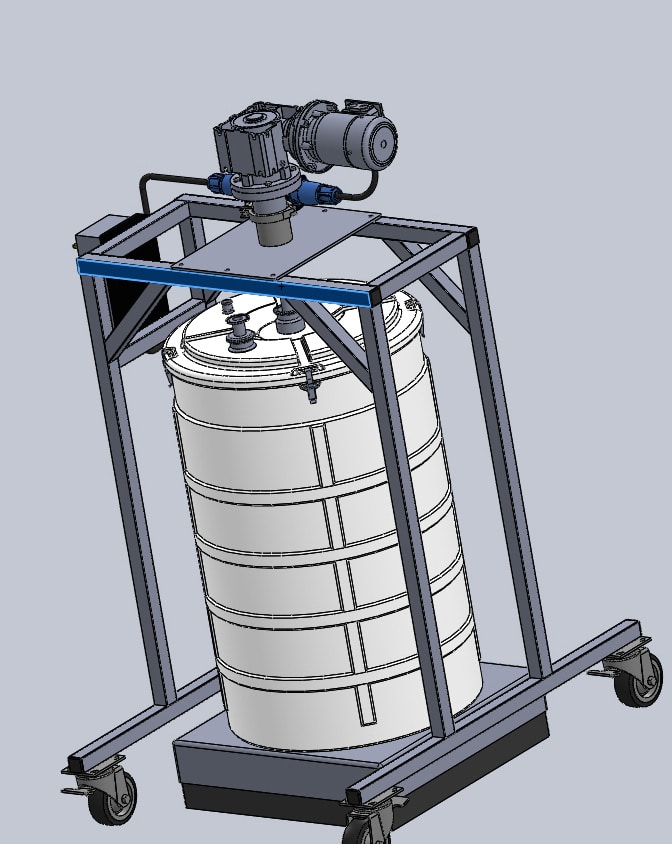

Sanitary C-Clamp Mixer on Poly portable push cart, used for mixing multiple sized carboys with single use disposable bag liners. Mixer has quick disconnect “tool-less” arrangement to easily remove shaft/impeller assembly. Disposable poly USP VI PP mixing impeller and shafts are also available. Poly carts and tanks are built to client specifications.

Benefits of Single Use Mixing

Some advantages of using a single use mixer include:

- Single use mixers tend to be user friendly

- Decreased risk of cross-contamination

- Smaller financial investment

- Ends cleaning validation and sterilization concerns

- Faster production times

- Increased accuracy

- Convenient and readily available storage

- Reduction in personnel costs

- Ready to use

- Adjustable output

- Elimination of need for tank and impeller cleaning

There are a number of significant benefits that accompany the implementation of single use mixing systems within the biological and pharmacology industries. The development, testing and manufacture of preparations such as vaccines, an array of specific cell cultures, pharmacological research, buffers formulation, and cell culture media prep all require precise mixing. In fact, any process that involves suspension, dissolution, dispersion and/or homogenization is dependent upon accurate and thorough mixing. The incorporation of single use mixers into bio-therapeutic development and production insures superior mixing and a more uniform end product. There is a wide variety of single use mixing systems on the market, most of which can be customized to address specific mixing needs.

Types of Single Use Mixing Systems

Single use mixers come in a wide range of designs. Both open and closed systems are common, and each category offers a number of variations, each best suited for a specific type of application. Sub-categories include:

SINGLE USE BOTTOM ENTRY MIXERS

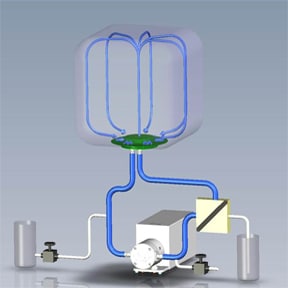

Single use mixers using traditional disposable bags, with a bottom entry mixer design which is guaranteed to not shed or fail. There are no moving parts on this blender design which provides more uptime, zero chance of failure, and no worries on particulate shedding which can be an issue on traditional plastic magmixer designs.

WMProcess bottom mount mixer design is a new innovative Single Use Mixing System. Using a single use pumphead, this disposable blending equipment becomes a multi purpose bioprocessing system for:

- Single use mixing of solutions by recirculation, without rotating wetted mixer parts.

- Integrated filling and emptying of the bag

- Post mixing processes like sterile filtration, TFF, flow through chromatography and others

- Optional integration of in line single use sensors (including sensors for pH, conductivity, temperature, and UV)

- Optional integration of a heat exchanger for cooling and heating of the media

- Excellent disposable mixing system for buffer, media, and sterile processing

Principle: the QuattroMix Single-Use Mixing System has an inlet and outlet port which both are connected to a pumping device. Through the outlet port the media will be pumped out of the bag, circulates through the pump (and other possible post-mixing processes) and will be pumped back in the bag through 16 nozzles with a smooth fluid stream.

WMP Mixing Bags are available from 10liters to 2000liters.

Mechanical Drives

With shaft mounted pitched-blade turbine style impellers

Because of their powerful coupling (direct drive) and high torque delivery, these mixers are appropriate for liquid/liquid operations as well as powder/liquid operations. They are available both open and closed, and can be mounted on the top or bottom. They function well in automated systems with online sensors, and are applicable for buffer and/or media preparation, virus inactivation, to control pH, end-stage formulation and also, filling.

Paddle Mixers

This closed-style mixer provides vertical paddles which rotate, creating radial flow patterns. Other than the paddle, they have no moving parts. Therefore, they’re often preferred for particle sensitive operations like aseptic manufacturing lacking final sterilization filters. They are the mixer of choice for any final aseptic operation, or for purposes such as cell culture media, suspension and re-suspension in the course of purification, the preparation of chromatography sorbent slurry, etc.

Stir Rod/Wand mixers

These mixers are typically chosen for open and closed small volume mixing applications. They are suitable for media and buffer prep work, suspension and re-suspension, purification purposes, TFF and end-stage formulations.

Levitating & Magnetic Mixers

Similar in some ways to paddle mixers, these closed style mixers also use vertical paddles. They function well in large scale liquid/solid and liquid/liquid applications such as buffer/media prep. Magnetic mixers are useful in heavy-duty applications because they provide the power required for heavy loads such as in the dissolution of dry powder media cultures. Levitating mixers are especially well suited for applications in which extreme cleanliness is critical. Later stage downstream processing, aseptic vaccine production when final sterile filtration and/or particle removal is unavailable, therapeutic cell media prep, etc. are all good examples. The lack of moving parts, bearings, shafts, etc. within the mixing bag eliminates friction that might otherwise possibly create unwanted particles.

Orbital Shakers from White Mountain Process

Our Orbital Shakers are perfect for blending buffers, proteins, chromatography slurries and a great choice for mixing with either carboys or single use bags.

Orbital Lab Shakers are known for their ability to provide low shear and gentle blending, to more vigorous shaking and mixing action. Shakers are heavy duty and robust, easy to use, and extremely effective at mixing very quickly and uniformly.

Orbital Shakers typical options we can provide:

Biopharma ready, complete documentation packages, IQ/OQ optional, FAT testing optional.

Heavy Duty Large Volume Mixing and Small Volume blending

Fixed Speed or Variable Speed / High or Low Speed

Variable Speed digital display with digital countdown timer

Temperature controlled top plate typical

Explosion Proof and Hazardous Duty motors available

Remote Control Operation available

All Stainless Steel Models

Incubator High Humidity and CO2 gassed models

Single-Use Jet Mixers

With Gamma Radiated Disposable Single-Use Bags

Another closed system that employs suction which draws liquid from its top that it then expels via directional ports. Single-use jet mixers are user friendly, portable and economical, and work well for clean operations such as the homogenization of fluids, or the re-homogenization or re-suspension of previously stored fluids.

A single use mixer need not be complicated. It is possible for such a mixer to be as simplistic as a two dimensional container on a rocker table or a disposable 3D liner placed inside of a mixing tank. Single use mixers graduate in complexity, particularly within closed systems that employ mechanical drives. Regardless of their sophistication, they all serve the same purposes. Above all else, single use mixers increase efficiency, keep costs low, and are integral to the production of a quality product.

SINGLE USE MIXERS AND BIOREACTORS

Say goodbye to lengthy downtime with super-fast turnarounds.

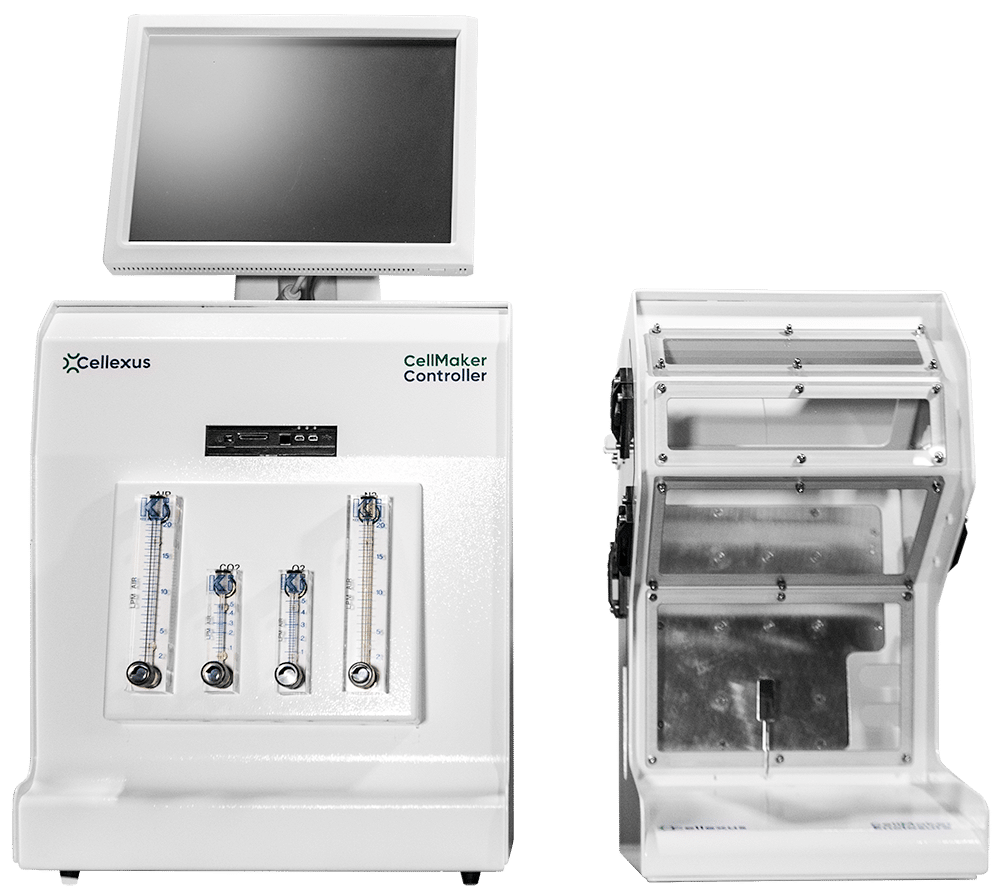

The specially designed CellMaker airlift single-use bioreactors have been created to perfectly suit our system and your application. These single-use bags are easily replaced within minutes for a fast turnaround so you can start on your next process.

These sterile bags are fitted into the enclosure and the contents are agitated by bubbles created by a customizable influx of gasses. Our robust system is designed without any moving parts, eliminating the chance of mechanical failure. In addition, gentle agitation from our bubbles reduces the risk of cell shearing usually associated with agitated mixing impellers. Single use disposable mixing bags are available in sizes 8 Liters and 50 Liters to suit your enclosure, and provide working volumes of 3L to 8L, and 10L to 50L.

Our CellMaker Regular Bioreactors are compatible for use with our CellMaker Regular Controller and CellMaker Plus Controller. While our CellMaker Plus Bioreactors are designed for use with our CellMaker Plus Controller only. These bags contain a sensor for measuring dissolved oxygen and a pH port making these bags ideal for providing precise control over more challenging processes.

Regular

• Touchscreen interface / CellMaker software

• Accurate mass flow controller Air / O regulation

• Pressure sensor allows automatic shutdown in case of over pressure

• Front rotameter for visual control of gas flow

• Compatible with both 8L and 50L Enclosures

• Optional automatic feed addition via external pump

PLUS

• All the benefits of the Regular system, plus:

• Fitted with pH meter allowing pH monitoring and automatic control via dual acid/base pump and CO2

• Fitted with Dissolved Oxygen meter allowing pO2 monitoring and automatic control using O2