Aseptic High Purity Polypro and HDPE Mixing Tanks

PROCESS SCALE BIOSEPARATIONS FOR THE BIOPHARMACEUTICAL INDUSTRY – Built to your specs

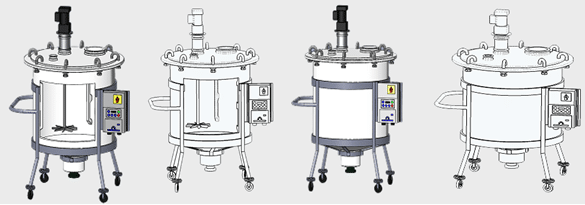

We manufacture a variety of open top, hinged lid top and sealed – vapor tight mix tank setups built to your application requirements.

Agitated cGMP biopharma ready poly vessels that are sealed (vapor tight and GMP tank design).

Mixing Equipment

For Bioprocess Engineers

WMP has been providing “mixing solutions” to industry professionals for more than two decades.

Polypro and HDPE blending vessels built to your specifications:

Mix Tank Sizes Available from 1 liter – 5,000 gallons

View our gallery of poly mixing tank systems

- Sanitary duty (FDA PE and PP sanitary agitated vessels. Typical for food blending, beverage, dairy, cosmetic mixing)

- Corrosion Resistant (non-metallic mixers and agitated mix tanks with a variety of materials available including PE, PP, PVDF, PTFE, exotic alloys such as titanium and Hast C, cGMP and USP VI poly materials readily available)

- Biopharma duty (cGMP process vessel in USP VI Polypro or USP VI PVDF with agitator typically 15Ra and electropolished 316Lss wetted parts, material certs, doc package, USP VI on any elastomers, typical for buffer prep, media make-up, vaccines, bioreactors, filter hold agitated vessels, chromatography makeup)

- MIX TANK SIZES AVAILABLE = 1 liter – 5,000 gallons

- Custom engineered mixtank packages designed for your specific application. Please note we offer premier sanitary and industrial duty engineered mixtanks, these are not typical substandard tank/mixer packages you can find online or in catalogs.

TYPICAL APPLICATIONS:

- DI and Ultrapure Water Storage Tanks

- Buffer Prep Agitation, Dissolving of Salts

- Media Slurry Tank -Chromotography Slurry Agitation (baffled tanks with Chrome Slurry Mixer design)

- Diagnostic Mixing and Storage

- Non-Metallic Mixing and Blending Systems

- Vaccine Blending

- Filter hold mixtanks

Polyethylene / Polypropylene / PVDF / PTFE / 316Lss / Hast C – and other mixtank materials of construction. FDA + USP VI poly mixtanks and Industrial/Sanitary/BioPharma metal and stainless mixing vessels.

Simple mixtanks to complex mixing systems available – we can include CIP spray nozzles, riboflavin cleanability testing, pressure relief valves, instrumenation, thermowell and RTD, flush mount poly tank fittings, aseptic diaphragm valves, etc.