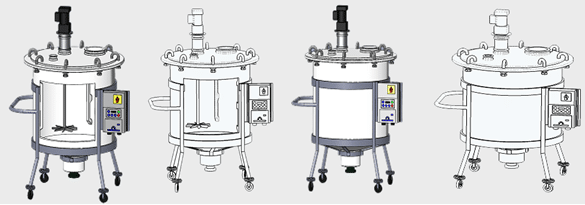

Complete Mixing Tank Packages

PE, PP, PVDF, or Stainless Mixing Tank Packages

Process Systems Built to your specifications

Blending vessels can be poly plastic (PE, PP, PVDF most common) or stainless steel (304ss and 316ss most common) as desired.

Mixing Equipment

For Bioprocess Engineers

WMP has been providing “mixing solutions” to industry professionals for more than two decades.

Process blending vessels can be poly plastic (PE, PP, PVDF most common) or stainless steel (304ss and 316ss most common) as desired.

Automated or semi automated blending systems offer a precise and repeatable process which is able to be validated.

Typical blending system specifications and bill of materials can include:

- Process Tank – stainless or plastic

- Mixer – air or electric operated agitator

- Industrial or sanitary design, cGMP as specified

- Heating or cooling

- Pressure or vacuum

- Mixer speed controller

- Agitator tachometer

- Low Shear Mixing System

- High Shear Mixing, dispersing and homogenizing

- Batch and inline mixing/blending

- Top and bottom entry mixers

- Inline high shear and static mixers

- Valves

- Instruments

- Temp and pH control

- Manways and ports

- Sight glass

- Pumps

- Pressure relief valves, rupture discs, hepa filters, vent filters

- Dust collector, solid feeders

- Metering pumps

- Heating and cooling temperature control units

- CIP spray wands, balls, nozzles

- CIP system

- FAT

- Document packages

- On site installation and service