High Viscosity Mixers For Lotion, Balm, & Cream Manufacturing

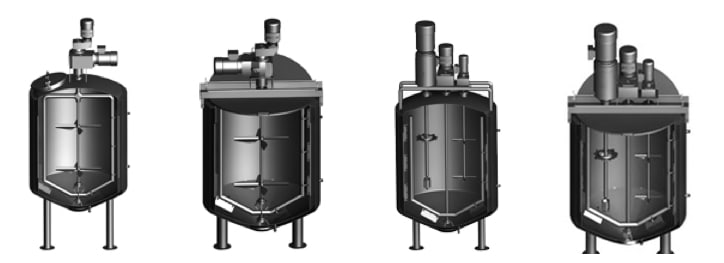

- Dual Shaft or offset mount dual motion mixer – a Dual Shaft mixer uses a center mounted low speed shaft with an offset high speed shaft. The Dual Shaft Agitator will handle a good majority viscous mixing applications.

- Concentric Dual Shaft or concentric mount dual motion mixer – a Concentric shaft mixer uses a center mount hollow low speed shaft, with the high speed shaft in the center as well. The high speed disperser or agitator blade can be larger than on an offset high speed design so for an application which requires more shear this would be a benefit.

- Triple Shaft or offset mount triple motion mixer – The Triple Shaft mixer is similar to the Dual Shaft design, the difference is the addition of second offset high speed shaft. The two high speed shafts are located opposite each other. It is very typical to use a high speed agitator impeller for bulk flow and a high shear disperser for high tip speed. Sometimes a rotor/stator high shear mixer is used or a squirrel cage type shearing head. Having two high speed shafts allows for very rapid solids dispersion, emulsification, and homogenization of the batch.

- Concentric Triple Shaft or concentric mount triple motion mixer

- Sweep anchor with baffle – this is often a way to save capital cost and utilize a single anchor paddle agitator and use a baffle to help provide the bulk blending and uniformity needed.

- Bottom Entry High Shear – this design is commonly used with the concentric triple shaft style agitator.

- Dual motion horizontal scraped surface ribbon blender – this is a horizontal blender typically used for viscous food processing.

- Teflon PTFE wall scraper on the anchor – a PTFE sweep blade scrapes the tank wall which provides excellent heat transfer and continually cleans the wall from sticky fluids.

- Heating and cooling jacket – for temperature control of the mixture.

Typical operating speeds of multi agitators are:

- Anchor Wall Scraper: 5-30 RPM

- Top Entry Turbine Agitator: 50-350 RPM

- High Shear Mixer Disperser: 1750 RPM / 3600 RPM

- Bottom Entry High Shear Mixer Homogenizer: 1750 RPM / 3600 RPM

PRE-ENGINEERED LABORATORY MULTI SHAFT MIXER AGITATOR PACKAGES

- 25gal -5000gal size ranges

- Dual shaft mixer with high torque anchor paddle and agitator or high speed disperser

- Triple shaft agitation, teflon scraper anchor mixer, turbine agitator and high shear mixer (top or bottom entry high shear available)

- Stainless steel wetted parts

- TEFC inverter duty motors

- Stainless steel sanitary tank, single wall and jacketed for heating and cooling

Options:

- XP Explosion proof or air operated motors

- Teflon wall scrapers

- Multiple impeller options

- Mixer speed controllers

- Custom mixing vessel, outlet valves, pump, jacket for heating/cooling