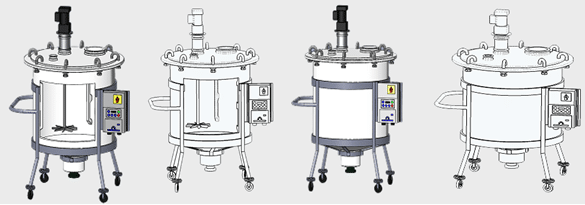

Poly Mixing Tank Systems Typical Documentation for Sanitary cGMP Blending Vessels

Optional Documentation: Weld qualification and inspection records available P+ID drawings as required (Process and Instrumentation diagrams) Electrical drawings FAT report (Factory Acceptance Test Report).

WMProcess can perform and document the Factory Acceptance Testing of the mixing tank system prior to shipment and video tape aspects of the test. Testing will include a step-by-step written verification test of all software and hardware functions. Customer welcome to visit for FAT. SAT (Site Acceptance Test Report) as required.

IQ/OQ Document – we can assist as needed.

Cleaning and Passivation Report Video instructions for mixer installation and maintenance.

Weld Video Record (Digital recording of boroscope weld inspection) Instrument Data Sheets.

Static water hydro test report Poly mixtanks are not pressure rated, so static hydro test provided with documentation.

Mixing Equipment

For Bioprocess Engineers

WMP has been providing “mixing solutions” to industry professionals for more than two decades.

Drawings – 2D dimensional and 3D drawings used

- Mixer performance data (flow, turnovers/min, hp, torque, tip speed)

- Installation, Operation and Maintenance manuals

- Recommended spare parts list

- Instrument + Equipment lists

- Instrumentation calibration procedures

- Material Certificates (MTR’s for 316Lss and metals and FDA/USP VI for elastomers, certificate of compliance)

- Surface finish report (profilometer testing available, coupons used for appearance, coupons used for poly finish and poly welds)

- Vessel drainage test report

- Inspection test results, reports and certificates

- Component catalog cut sheets

- As built mixer and tank drawings

- Passivation and Electropolish certs

- Poly nozzle weld spark test reports

- Mixer run test