Biopharma-Grade Mixing Systems, Agitators, & Mix Tanks Customized to Your Process Specifications

Mixing solutions for over two decades, specializing in bioprocessing, biotech, and pharmaceutical applications.

FIND YOUR MIXERS

Built To Your Specifications

Sanitary & Single Use Mixing Systems

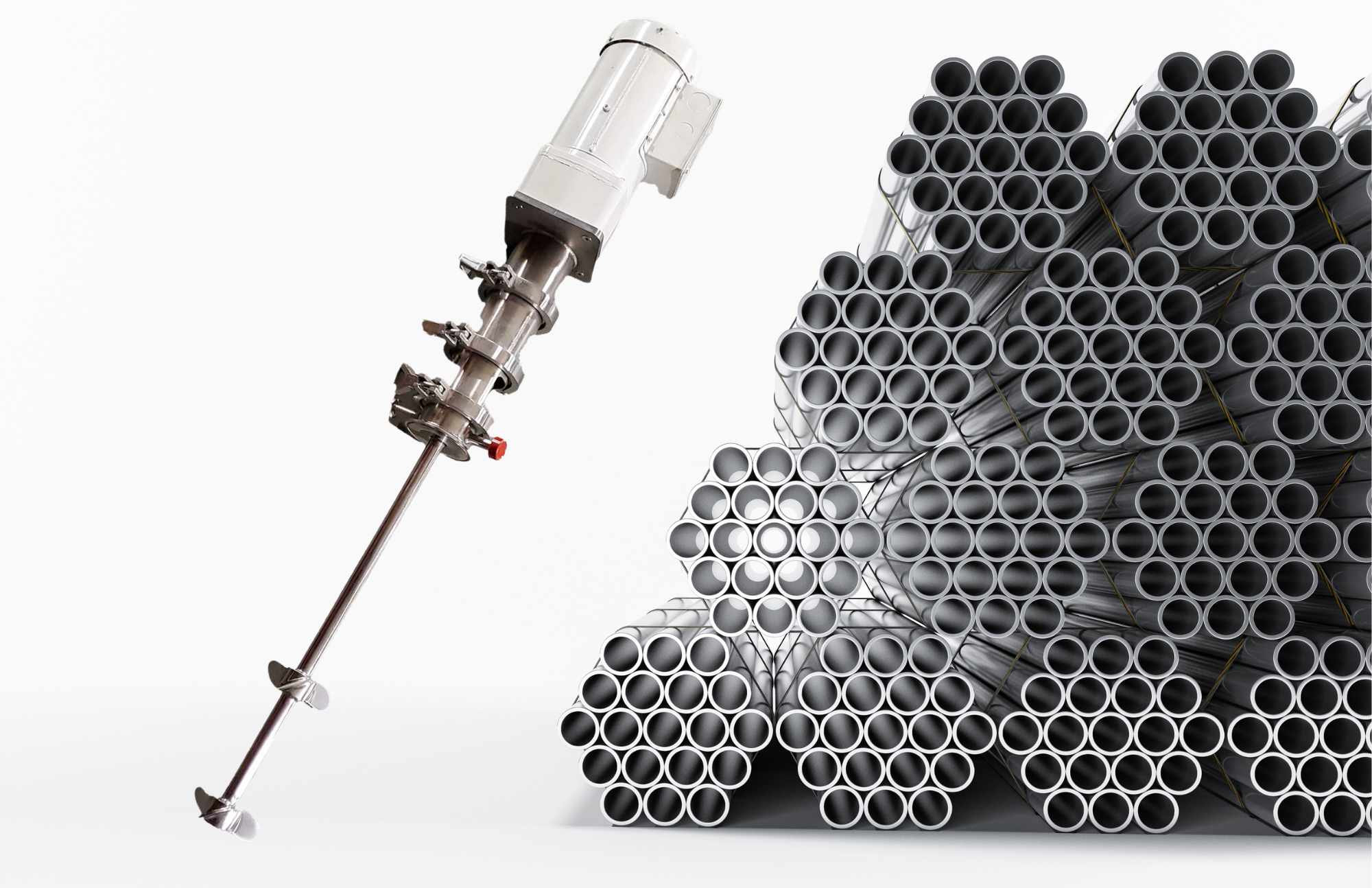

Agitators, Mix Tanks, & More

Trusted mixing experts for more than two decades

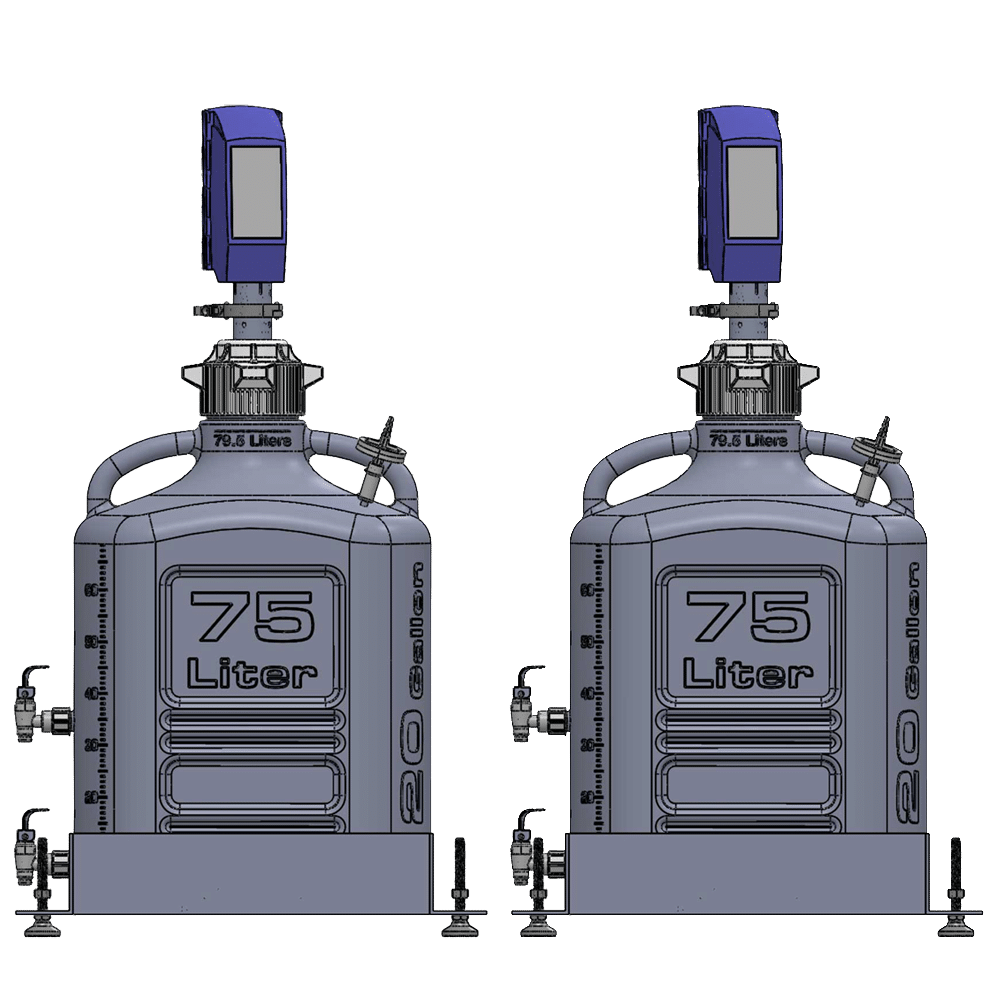

Sanitary Plastic Mixing Systems

USP VI PP or HDPE Chemical Mixing Systems – 5 liter to 1,000 gallon built to your specifications

Bioprocessing tanks (blending systems) for buffer prep, media prep, mixing liquids, or dispersing powders into liquids.

Multiple agitator options available.

5 liter to 1,000 gallons are readily available, with a complete GMP documentation package and all certifications.

Sanitary Laboratory Carboy Mixers – Agitators

Autoclavable and portable, our carboy mixers are built to your specs. Contact us today for a fast quote.

We are a USA-based full-service mixing equipment manufacturer with over 20 years of experience providing professionals with specialty equipment for their exact bioprocess needs.

Mixing Equipment

For Bioprocess Engineers

WMP has been providing “mixing solutions” to industry professionals for more than two decades.

1 Liter – 10,000 Gallon Mix Tank Sizes Available

Stainless – Poly PE – PP, PVDF, PTFE, Titanium, Hastelloy C, & More

INDUSTRIES WE SERVE

Biopharma Mixing & Blending

Skincare Product Blending

Chemical Mixing – Powder Blending

Beverage Mixing & Blending

Plant Extraction & E-Liquid Mixing

Biodiesel Production

WHITE MOUNTAIN PROCESS USA

White Mountain Process is a premier USA-based developer of sanitary mixing + blending equipment, specialty mixers, and industrial agitators.

We provide mixing expertise and engineering assistance to help our customers select and implement the best mixing equipment for their needs.

Located on the East Cost, we ship in the USA and internationally.

As mixing and system design specialists, we provide custom and standard mixing and blending equipment for applications in many industries, with emphasis on sanitary mixing, blending, and agitator mechanical seals. Due to our high quality standards and extensive cGMP biopharma process expertise, we are best known for our biopharmaceutical and biotech mixing equipment.

However, we offer a full range of mixers and blending products for other applications and industries. If you need to mix ink, buffer, saline, mash, food, pharmaceuticals, or nearly any other substance, we likely have the mixing solution for you.

Quality is our primary service.

APPLICATIONS WE WORK WITH

Discover the benefits of world-class engineering and our White Mountain Peak-performance Team. We’re committed to making your job easier. (Much easier!) Ask about our proprietary squeal-less dry-running mechanical seal for controlled-humidity environments. It’s blissfully quiet in performance!